BEL Technologies

BEL machines have one of the smallest footprints in the industry due to the use of our Snap Folder technology, allowing for safe operation with minimal guarding. Highly customizable with a number of options and accessories, BEL machines are designed to be a modular, compact, packaging solution that is able to grow with your business. Each of our machines are made in North America, backed by one of the largest service networks with top tier Wexxar Bel service technicians ready to answer all your questions.

Snap Folder Technology

Snap Folders is the folding technology used on BEL fully automatic case sealers for folding the trailing minor flaps. Folding the trailing minor flap on case sealers had always been a difficult task, due to the tradition way of manually folding the flap or using a heavily guarded machine with a "kicker" to knock down the flap.

Snap Folders are able to safely fold the trailing flap with no guarding due to its unique design. Compared to "kicker" style machines, Snap Folders lightly and quickly hit the flaps to fold the corrugate without the risk of harming the box or operator. Even without additional guarding, Snap Folders are safer than conventional "kicker" style folders as it is extremely unlikely for injury to be caused by a Snap Folder. This innovation allows the machine footprint to remain small for applications with space restrictions. An example would be the BEL 270, which is the most compact automatic hot melt case sealer on the market.

Easy Color Coded Size Changeover

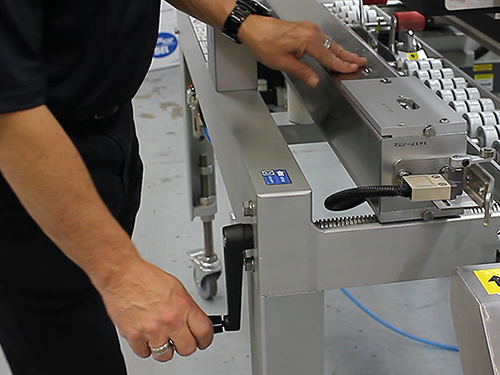

For most packaging machinery, case size change is likely the most difficult task an operator must perform. With Wexxar BEL machines, machine pictorial guides and color coded size change handles are used with exact step-by-step instructions also located on the machine. These pictorial guides make it easy for anyone one to understand by utilizing a universal textless color system that is easy to follow.

BEL machines have very few changeover points - usually 3 or less. With the pictorial guides and color coded rulers to quickly identify where each changeover point is, the changeover can take less than 5 minutes.

Additional Features

Dynamic Flap Folding

BEL case formers utilize a dynamic flap folding system to ensure reliable, consistent folding while also keeping the machine footprint to a minimum.

Modular Machine Design

BEL machines are modular in design to adapt to the changing needs of your production line.

Uni-Drive Technology

A single motor drives both belts to ensure there is evenly distributed power between both belts even after extended use, eliminating potential case skew that comes from multiple motor drives.